Lasting Machines

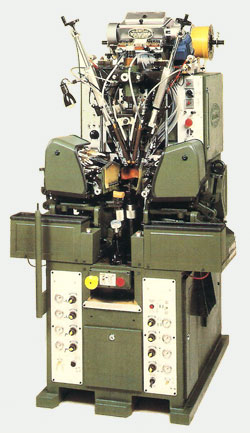

Automatic Side Heel Laster Model T (ASHL-T)

Download Specs KB (pdf)

Our lasting system is unique to the shoemaking industry. We do pulling and toe lasting first, then the sides are lasted and the heel tacked with 8 to 26 tacks. With the new ASHL-T, you can produce clean joints and flat bottoms while realizing greater cost saving, increased production, and consistent quality.

- Produce up to 200 pairs per hour, 250 pairs of heel seat lasting only.

- Powerful heel seat tack driver adjustable for 8 to 26 tacks and two different tack lengths can be used simultaneously if required.

- Special pincers in the breastline area.

- Fingers for shank, ball, and forepart ensure continuous smooth drafting and bonding.

- Efficient, cost-saving rod-type adhesive system.

- Lasting of ball, shank, and heel seat in one operation.

- High last spindle jack accommodates high and narrow boots.

- Capable of handling heavy, fine, and sport shoes in all sizes and heel heights.

Specifications

Air:

Pressure:

85 lbs./in.2 (6 Bar)

Consumption:

4.5 scfm (125 liters/min.) at 150 pairs per hour

Electrical:

208-240V, 60 Hz, 10A 3 phase, 3.5 kW peak

Weight:

Gross: 2580 lbs. (1170kg)

Net: 1985 lbs. (900kg)

Net: 1985 lbs. (900kg)

Dimensions:

48W x 56D x 80H inches

(1150W x 1,400D x 1,950H mm)

(1150W x 1,400D x 1,950H mm)