Lasting Machines

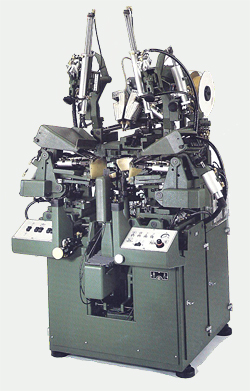

Automatic Side and Heel Laster Model GP/G (ASHL-GP/G)

Download Specs KB (pdf)

Our two machine lasting system reduces cost because the shoes are completely lasted in two operations, pulling over and toe lasting first, then lasting the forepart, ball, shank, and heel seat. This assures quality and consistency.

- Breastline pincers on ASHL-GP for tighter lasting quality and appearance.

- Self adjusting pressure pads for tight lasting of foreparts, balls and shanks.

- A high speed last spindle jack permits high and narrow boot lasting without adjustments.

- Lasting of heavy, fine, casual, fashion and sport shoes in all sizes and heel heights.

- Double wiping by heel wipers.

- Economical rod-type adhesion system.

- Production rates of up to 200 pairs per hour.

Specifications

Air:

Pressure:

80 lbs./in.2 (5.6 Bar)

Consumption:

7.2 scfm (203 liters/min.)

Electrical:

208-240V, 50/60 Hz, 10A single phase, 2.0 kW peak, 1.5 kW average at 200 pairs per hour

Weight:

ASHL-G: 1620 lbs. (735kg)

ASHL-GP: 1700 lbs. (771kg)

ASHL-GP: 1700 lbs. (771kg)

Dimensions:

ASHL-G: 36W x 56D x 64H inches

(914W x 1,422D x 1,625H mm)

(914W x 1,422D x 1,980H mm)

(914W x 1,422D x 1,625H mm)

ASHL-GP: 36W x 56D x 78H inches

(914W x 1,422D x 1,980H mm)

Weight:

ASHL-G: 1620 lbs. (735kg)

ASHL-GP: 1700 lbs. (771kg)

ASHL-GP: 1700 lbs. (771kg)

Construction:

Metric System Construction