Lasting Machines

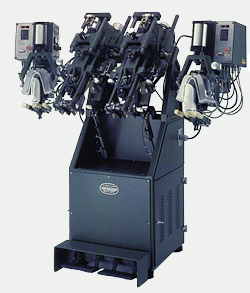

Heel Molder and Flanger Model J (HMF-J)

Download Specs KB (pdf)

The Heel Molder Flanger Model J is used for thermo-coated fiber or thermoplastic counters. After being heat softened by heated activator molds and pads, the uppers are shaped and flanged on cool forming molds. The activating temperatures and times are electronically programmed for constant, proper activation. The operation is efficient and can be performed by unskilled operators.

- Mirror allows visual check for back seam straightness.

- Back height accurately set by gauge ensuring correct size by size back height.

- Curved adjustable pincers draft upper and lining tightly around mold.

- Wipers to flange heel seats.

- Adjustable mold positions for accurate heel seat forming.

- Molds and pads can be quickly changed.

- Production rates of up to 125 pairs per hour.

- Regular or custom made molds.

Specifications

Air:

Pressure:

80 lbs./in.2 (5.6 Bar)

Consumption:

5.6 scfm (158/liter/min.) at 125 pairs per hour

Electrical:

220 V, 60 Hz, 4A single phase

3.3 kW peak, 2.1kW average at 125 pairs per hour

3.3 kW peak, 2.1kW average at 125 pairs per hour

Weight:

775 lbs. (352kg)

Dimensions:

69W x 35D x 66H in.

(1,755W x 890D x 1,680H mm)

(1,755W x 890D x 1,680H mm)